You've heard that 'one bad apple spoils the whole

barrel', right? It's true. Bruised, damaged, or overripe fruit gives off a

hormone that accelerates the ripening of the other fruit -- ETHYLENE.

What is

ETHYLENE ?

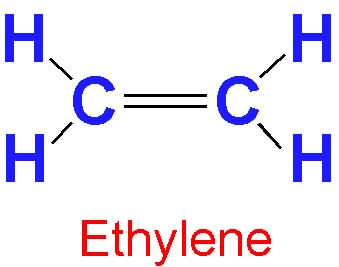

Ethylene (C2H4, also known as ethene) is a

gaseous organic compound that is the simplest of the alkene chemical structures

(alkenes contain a carbon-carbon double bond). Ethylene is the most

commercially produced organic compound in the world and is used in many industrial

applications.

Plant tissues

communicate by means of hormones. Hormones are chemicals that are produced in

one location that have an effect on cells in a different

location. Ethylene is the hormone that will cause a wide range of effects

in plants, such as fruit ripening, loss of chlorophyll, abortion of plant

parts, stem shortening, abscission of plant parts, and epinasty (bending of

stems) which depending on the age of the plant and how sensitive the

plant is to ethylene. Ethylene can be either good or bad, depending on what

merchandise you work with. It is used in a positive manner in fruit ripening,

for instance. It can also cause damage in crops. Examples of damage might

include yellowing of vegetables, bud damage in dormant nursery stock, or abscission

in ornamentals (leaves, flowers drop off). Most plant hormones are

transported through the plant vascular system, but some, like ethylene, are

released into the gaseous phase, or air.

Where does it come from?

Ethylene is produced and

released by rapidly-growing plant tissues. It is released by the growing tips

of roots, flowers, damaged tissue, and ripening fruit. The hormone has multiple

effects on plants. One is fruit ripening. When fruit ripens, the starch in the

fleshy part of the fruit is converted to sugar. The sweeter fruit is more

attractive to animals, so they will eat it and disperse the seeds. Ethylene

initiates the reaction in which the starch is converted into sugar.

Commercial Use of Ethylene to Ripen Fruit

Climacteric fruits are frequently harvested at a

physiological stage that is considered ‘commercial maturity’, typically in a

hard green but mature stage just before ripening has initiated. Examples

include bananas, mangoes, tomatoes and avocados. This enables the fruit

to be harvested, cooled, stored and transported significant distances to where

it will be marketed and consumed.

Ripening can then be conducted under controlled

conditions of temperature, relative humidity and ethylene to achieve uniform

appearance and quality of ripe fruit. Fruit is placed into specially

constructed ripening rooms and brought to optimum ripening temperature and

humidity. Ethylene is then raised to a prescribed concentration using

either a "catalytic generator" that makes ethylene gas from liquid

ethanol or from commercially available gas supplies. Forced-air cooling

systems ensure that fruit are uniformly exposed to the room ethylene

concentration. When fruit are exposed to ethylene under these controlled

conditions they will initiate their respiratory climacteric pattern and ripen

at a relatively uniform rate. Conditions and duration can be varied to

suit customer specifications for stage of ripening and colour development.

However, concerns are periodically raised in

mass media about fruit being ‘gassed’, implying that this confers some residual

food safety risk from the ethylene gas and that the fruit has been somehow

rendered ‘unnatural’. The public should understand that the commercial

use of ethylene for fruit ripening is at a low concentration and simply

initiates the respiratory climacteric. The ethylene used commercially has

the same molecular structure. By the time the ethylene-treated fruit

reaches the consumer the climacteric may have started, there is no trace of

applied ethylene gas, any ethylene emitted by the fruit is generated by the

fruit itself and is of a much greater concentration. Therefore, there

are no food safety issues associated with the consumption of climacteric fruit.

No comments:

Post a Comment